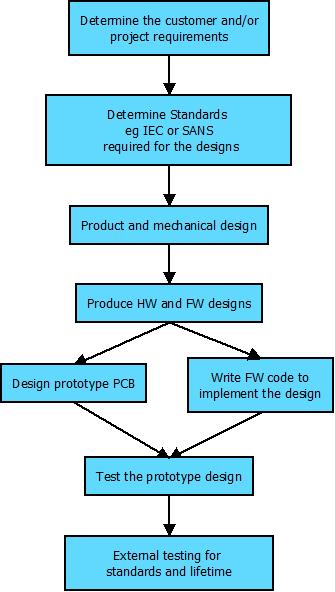

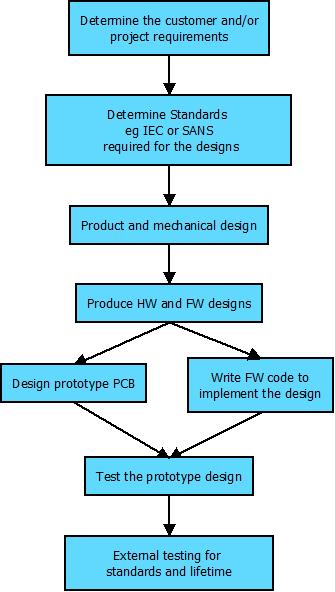

There is an engineering cycle for product development. Sometimes the customer does not have complete engineering requirements, and this means we need to work with the customer to define what they want. There are also cost reasons why some parts of the cycle may not be fully pursued. An example is the hardware and software design which may only be written on A4 paper instead of 50 or more pages of technical documents. A $1000 prototype does not merit this level of documentation

The standard design cycle is pictured above. This does not include scaling up for high volume manufacturing. As stated above not all steps may be detailed when constrained by costs or other factors.

It is important to adhere to national or international standards to allow your product to be sold in different countries. Prototypes or very small production runs can be made without much attention to standards but there is a risk of the product being banned if a competitor files a complaint. There are also other legal risks such as claims for damages (Example EMI interferes with radio, TV, radar and other systems). A typical minimum hardware standard is CISPR 22:2008 or an equivalent like SANS222.

Firmware quality is also important for fault free operation. The more complex firmware becomes the greater the difficulty to reduce problems(bugs). Bugs can be anywhere from minor annoyances to life threatening. We can provide automated static checking and have built in standards compliance in some of our firmware tools (e.g. for MISRA). If requested we can provide almost any standard required

For high volume products and for products where safety or malfunction is an issue there is a need for the extra quality.

There is a need for production quality and records of testing and serial numbers, starting from low level production. We can help to get your product manufactured to ISO9001 with automatated camera inspections, before assembly and final test.